What you need to know about Surgical Instrument Marking

Introduction

Just about everyone these days wants their surgical instruments etched with 2D data matrix barcodes. There are plenty of benefits to be gained from doing so.

It speeds up the instrument assembly process and reduces the need for your people to memorise instrument names. The assembly process becomes very simple. Team members scan a barcode on an instrument and the computer tells them if it’s the right one or not and when the tray is complete.

Incomplete trays, incorrect instruments and tray compositions are a thing of the past.

But is it really as wonderful and simple as we are led to believe? Is this a “perfect world view” or the way it works in reality?

If you are considering going down this track there are many things to consider. So in this blog I’ll take a look at some of the things you really should know before you dive in.

Laser Marking Machine

To etch 2D data matrix barcodes the first thing you will need, besides instruments, is a laser marking machine. A good quality laser marker will set you back between $80-100K. So cost is a major factor to consider.

Different types of materials require different lasers for marking. One size does not fit all. For example, whereas Co2 lasers are good for acrylic, glass, textiles and plastics you will need a Fiber laser to etch metals, coated metal and plastics. YAG and YVO lasers on the other hand are good for metals and plastics.

Given that your inventory is made up of a diverse range of materials, some research is necessary to ensure you select the right tool for the job.

I recommend you ask prospective suppliers of your laser marking machine to mark a selection of your instruments so you can see that the equipment is suitable before you buy.

Staffing

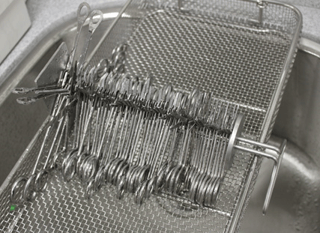

The logistics of getting your surgical instruments laser marked is a time consuming one. You will need to plan for one full team member to focus on this task alone. Each type of surgical instrument will require a different set up on the machine. There are different sizes, different materials and different levels of instrument complexity and fragility (i.e. artery forceps .v. ophthalmic forceps).

Capsulorhexis forceps, for example, are very fragile and can easily be damaged. Great care is needed moving these on and off the laser marker.

The marking machine settings for a chest retractor are completely different to the ones for ophthalmic forceps. Likewise, aluminum and titanium instruments will require a completely different marking profile.

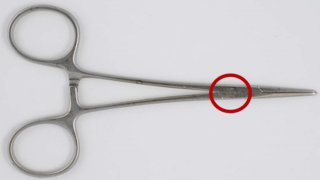

The picture above demonstrates a typical setup for an artery forceps. You can see how setup would differ for different types of instruments.

The picture above demonstrates a typical setup for an artery forceps. You can see how setup would differ for different types of instruments.

Therefore, to minimise set up time and make for the most efficient process, it makes sense to sort your instruments by their types and materials. This takes time to manage. In my experience you can reasonably expect to comfortably mark 6 instruments per hour (once your staff gain marking process competency).

OK, so let’s do some math. Let’s say a reasonable sized facility will have approximately 15,000 surgical instruments. If we mark 6 instruments per hour and multiply that by 8 hours = 48 instruments per day.

Multiply that by 5 days and you have marked 240 instruments a week. Now divide 15,000 by 240 and you will find that it will take 62.5 weeks to mark all your instruments. If you’re a bigger city facility you may have twice or three times that inventory. Do the math on that and your talking years!

Instrument size and material

Some instruments are made from materials that cannot be etched or do not etch well. Aluminium and brass are a couple of examples. Some things are just too small to etch. Try and get a readable 2D data matrix on an eye speculum or an instrument pin. It’s simply not possible.

Diathermy instruments provide a challenge as marking the insulation may compromise its insulating properties. What about limited use instruments - are you going to etch those?

What I’m saying here is that it won’t be possible to get a readable 2D matrix barcode on all your instruments. Depending on the type of surgical specialities your facility provides, this could be a sizable amount.

So what does that mean for our perfect world scenario where staff can assemble trays just by scanning the instrument barcode? Well it means perfect world just met with reality. There will always be instances where you need to manually pack and assemble instruments trays. Some trays may have some instruments marked and some not. This calls for an adaptive process that can handle both manual and automated packing scenarios making the process a lot more complicated.

Readability

2D Data matrix barcodes always read without fail right?

The reprocessing of surgical instruments can be a fairly rigorous process. Harsh chemicals, scrubbing and repeated wash cycles can diminish the contrast of the data matrix barcode. Stacking of instruments and rubbing of instruments against each other also can wear the barcode.

It is the contrast between the black and non-black that makes the barcode readable. As it fades, it will become less readable and provide inconsistent reads. It may not read as fast as it once did or it may not read at all.

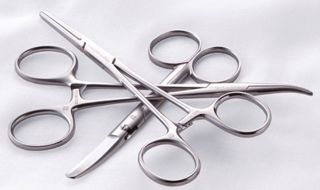

The picture above shows a pair of artery forceps with a

data matrix barcode.

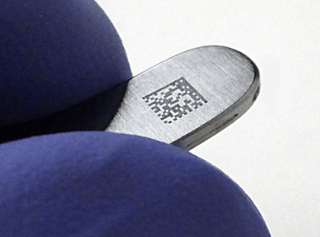

T he picture on the right shows a typical 2D data matrix barcode mark on a stainless steel instrument. What if, for whatever reason, this barcode won’t read? Given that the barcode represents the unique ID of the surgical instrument this would mean that everything you ever tracked about it has become irretrievable. You’ve just lost its sterilization history and all the patients it’s been used on. You’ve just lost its entire service history. In fact the instrument never existed!

he picture on the right shows a typical 2D data matrix barcode mark on a stainless steel instrument. What if, for whatever reason, this barcode won’t read? Given that the barcode represents the unique ID of the surgical instrument this would mean that everything you ever tracked about it has become irretrievable. You’ve just lost its sterilization history and all the patients it’s been used on. You’ve just lost its entire service history. In fact the instrument never existed!

Possibly the most valuable piece of advice I could give regarding Direct Part Marking is to mark a human readable component underneath the data matrix. That way if the barcode fails to read you can still read the number and type it into your tracking system. Even if that has faded and has no black at all, you will still be able to make it out under a magnifying lamp.

Conclusion

There is plenty to consider if you are thinking of going down the path of direct part marking your surgical instruments.

The main things to consider:

- The cost of a laser marking machine

- The type of the laser

- Instrument size and material

- Etching process workflow

- Staff resources

- barcode readability

- Retrieve-ability of tracking information